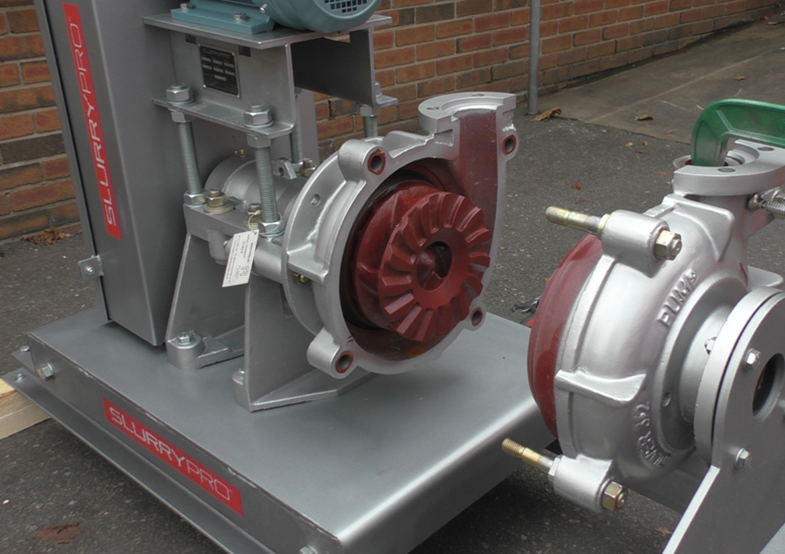

SlurryPro 377

About

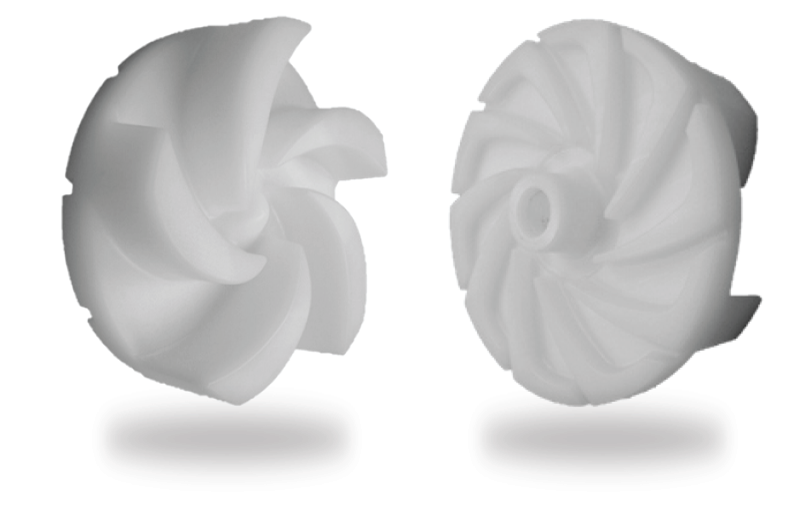

SlurryPro 377 material is a high density polymeric with excellent resistance to abrasion and chemical attack. It is available as impeller and volute material in SlurryPro horizontal pumps. It provides an excellent alternative for brines, fluids with crystallization and sludge chemicals, among others. It has the same dimensions as other coating materials such as SlurryPro 360 (rubber) and SlurryPro 331 (long-lasting high chrome) so it is interchangeable without modifying the pump.

377 Key Points:

- Temperature range - 100c to 80c

- Excellent impact resistance

- Low friction coefficient for better pumping efficiency

- Lightweight and extremely robust

- FDA approved for contact with food

- Excellent chemical resistance (ask for specific chemicals)

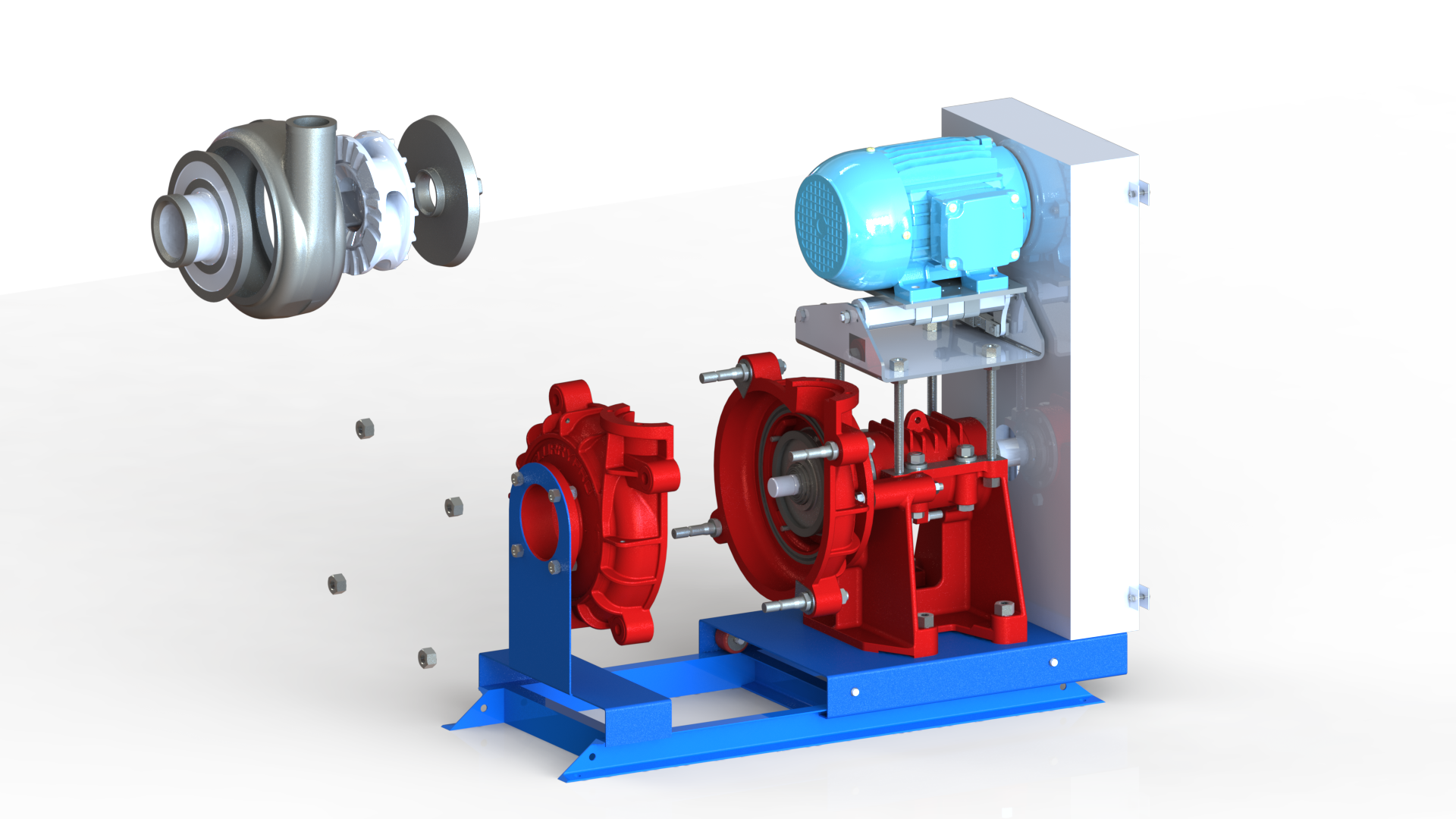

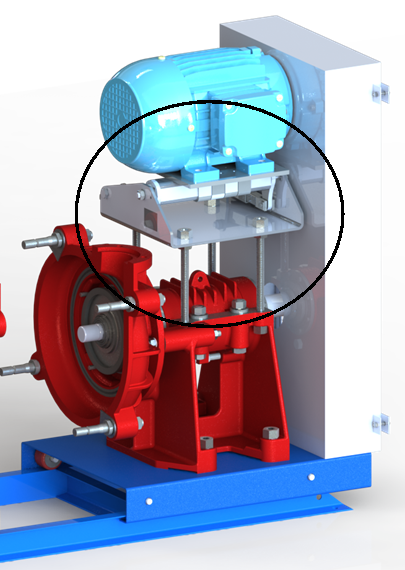

SlurryPro Self-Tightening Motorbase

SlurryPro pumps can also be fitted with a self-tightening motorbase. Here we detail some of the advantages.

- Ability to withstand shocks without the pulley snapping

- Automatically increases tension on the pulley, eliminating slack

- Much easier to remove the pulley for servicing or inspection

- Due to a consistent tension being maintained, this avoids heat being generated by the belt slipping, therefore avoiding belt failure

- Due to maintenance of ideal belt tension, less energy is consumed and the belt can last up to three times as long

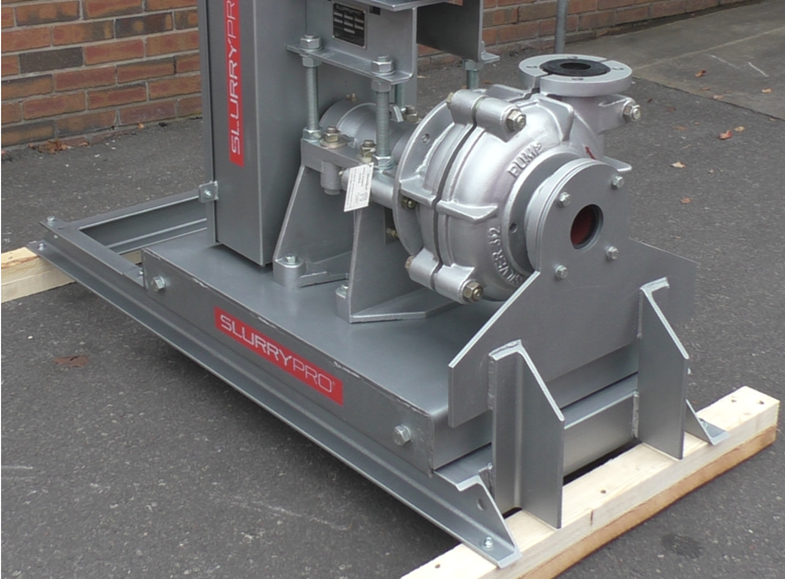

SlurryPro Sliding Base

Key Points

- An industry proven product

- Bespoke in-house design

- An ideal solution where space is limited

- Makes inspection and maintenance easier

- Reduces repair time, keeping any future downtime to a minimum

SlurryPro Sealing Arrangements

- Standard configuration is an expeller, which offers water savings compared to gland packing

- For more demanding situations we can fit a high-performance mechanical seal to your pumps

Intrax Pump Register

SlurryPro is a member of the Intrax Global Group, providing pump solutions to industry globally.

Background

One of the key promises to Intrax clients is that we aim to quote requirements within 30 minutes of the initial contact, then offer the fastest possible delivery time to minimise downtime.

We’ve been identifying the times we miss this, and generally we find it is because there isn’t the details available to the Site Manager regarding the pump that is being replaced or has gone down. The details may not be visible on the pump or the pump may have been running for years so details are no longer stored. This leads to the site having to wait for our engineers to arrive on site, then quote, and the delay causes costly downtime. To avoid this problem we’ve launched the Intrax Pump Register.

What is the Intrax Pump Register?

The Intrax Pump Register is an online tool upon which we record all the details of the pumps on your sites, including make, model, head, flow, application, general notes and a photo. We visit the sites, register all the pumps for you, and add a serial number and all completely free of charge, even making any recommendations for improvements too!

The Benefits of the Intrax Pump Register...

Massively speeds up quoting and delivery time if you have a pump that goes down.

Helps identify details when new spares are required.

Service reminders can be set up if needed.

Varying levels of access depending on number of sites covered.

In addition to the above points, the Register is also a portal where users can log in to and add their own pumps. The user can see the pumps they already have and, particularly on ready mix sites the register will help to standardize the pumps, which results in simpler maintenance and better pricing.

SlurryPro Mechanical Seals

Background

SlurryPro Mechanical Seals are available as both single and double seals and are designed to meet the arduous requirements of slurry applications. Large radial clearances and advanced multi-spring design give improved seal face loading and longer seal life. They are supplied as a complete cartridge to ensure they are delivered in pristine condition.

Slurrypro Mechanical Seals have been developed and are manufactured by a leading mechanical seal manufacturer. This means you have the confidence you are getting a pump designed for your industry, fitted with a seal from a trusted global mechanical seal manufacturer. A winning combination!