Did you know that one of the most common reasons for pump failure is due to lack of regular lubrication?

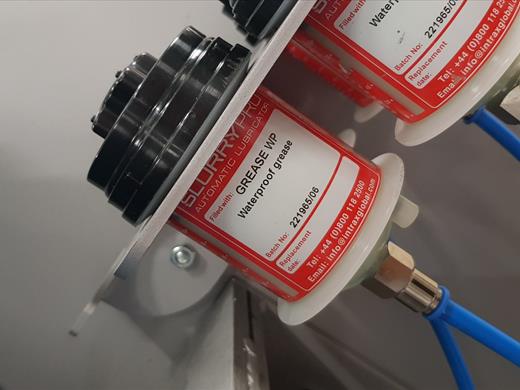

All new SlurryPro built-up pumps include provision for an automatic greasing system as standard. Once fitted, this ensures consistent reliable lubrication of the bearings and seals for maximum service life.

Manual greasing leads to both over and under greasing due to inconsistent or infrequent application. Over greasing leads to overheating, waste, pollution and premature failure. Under greasing leads to wear, premature repairs and high repair costs.

The Benefits of SlurryPro Automatic Greaser

- No further need for costly time consuming manual lubrication

- Labour saving/less labour intensive maintenance

- Improved health and safety

- Reduction in lubricant consumption

- Lessen environmental impact

Asset Reliability / Care

- Reduced costly downtime and failures

- Improved production performance

- Extend asset life

- Reduce maintenance costs

Availability and Fitting

UK manufactured SlurryPro Automatic Greaser pots are available individually and as part of a kit. The kit includes a bracket which can hold up to five pots of greaser, the greaser pots, nozzles and tubes. Thanks to the brackets' powerful magnetised material, fitting the bracket to the pump is a quick and simple procedure with no requirement for screws or tools.